Well Hello There Fellow Mechanics And Hivers.

My Last post in the #hivemotors community was one regarding the assembly of a transfer case for a 4x4 Nissan. This is somewhat of a continuation on that post and in this post I will cover the assembly of the transmission. It’s a tricky one, especially the stripping down of the transmission however I wont be covering the teardown in this post only the build up. Take note that not all steps are included sometimes I do need both of my hands to be able to do something properly so that I don’t have to redo it again.

Transmissions boy oh boy they can sometimes be a real pain in the ass, this is one of those times. I don’t really know why but this isn’t the most entertaining transmission to build up. Well it’s work who would have thought it should be entertaining? Well sometimes it actually is! Etc the transmission in my car is called a DCT250 and that’s a truely fun one to slap together.

Incase you might have missed the previous post where i rebuilt the transfer case check it out.

The Very First Transfer Case Assembly

Building The Transmission

Okay okay lets get down to it. I got my bucket of parts all mangled up and in dire need of a proper sorting! Now let’s see what was lost in the washbay, I know that one should always be positive and I am but the folks in the washbay always tend to lose a small part or two, perhaps even three.

Will this be the case today?

A worth while mention, I had to rewash these parts actually, they were washed on Friday afternoon and they were done sloppy, I rebuilt this box on Saturday so the washbay team was not at work.

But that's okay.

A Little Damage Assessment

So this transmission had it's fourth gear burned to bugger, absolutely nothing left. The problem with this is that it also buggers up the counter-shaft (Check second image below) Since the counter-shaft is a solid shaft, meaning you can't remove the cluster gear and replace it you've got to replace the entire counter-shaft and it's expensive. Real expensive. But this transmission will be completely rebuilt with good second hand parts.

The fourth gear is connected to the input shaft. So we will be replacing the input shaft as well. The fourth gear is the power gear in a manual transmission (In most cases) so when the fourth gear is bugger up you also don't have 1,2,3 and 5 however you will still have a fourth gear.

Funny ain't it? How is that possible when the gear does not have any teeth left? Well simple the fourth gear is direct drive so engaging the fourth gear sends the power straight through the gearbox and not through the counter-shaft, I know this is confusing. What happens is the sliding hub and the synchronizer connects with the tapered clutch body and joins the input shaft with the main shaft of the transmission and the mainshaft of the transmission is directly connected with the propeller-shaft this is why they call it direct drive.

Burnt fourth gear on the input shaft.

Burnt fourth gear on the counter-shaft.

Assembling The Main-Shaft

Funnily enough the third-gear is always the first gear to be installed, then the second and first gears.

I like to give it a little pinch in the bench clamp, although never on a machined surface. preferably on the output part of the shaft.

The main-shaft with the third-gear added as well as the hub and sleeve. All of this is held in place by a cir-clip.

Most of the benches in our manual transmission assembly room has a hole in. This is so that we can push the shafts through them in order to make the work a little bit easier.

So once the third-gear is added and cir-clipped into place I can now flip it over and slide over my second and first gears, in that order. Along with the hub and sleeve.

Main-shaft with the second, third and fourth gears added.

This is where the small parts come into play, notice just above the gear there is this spacer which is just a little bit bigger than the shaft. If you zoom in on the photo you can see that it has a little ball-bearing behind it.

Well that ball-bearing is around 1.5 mm in diameter, so dropping that would be. Well that would be sad.

Okay Okay, before I continue I got to fill the tummy eyy? I grabbed myself some muesli and yoghurt from the fridge.

I mean after all it was Saturday, I can probably take my sweet damn time?

Binding It Up

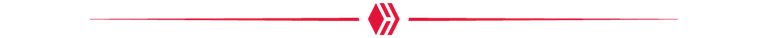

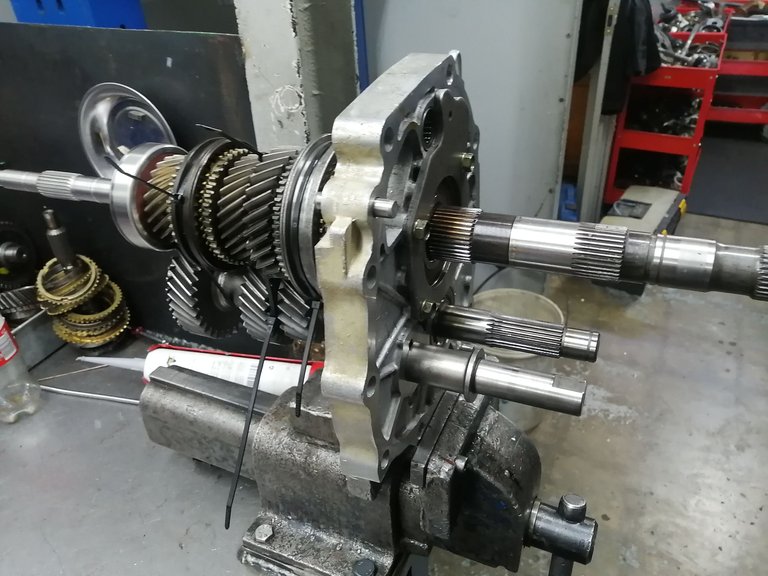

After getting a nice second hand counter-shaft and input-shaft I now need to cable tie them together for the next stage of the build. Making sure they are nice and tight because these parts are heavier than they look believe me that's some solid pieces of metal.

Also whenever I am uncertain of how to puzzle the pieces, a quick glance at the counter-shaft can give you a lot of information. I mean it's basically the other half of the puzzle already assembled!

Adding some cable-ties to hold the two shafts together for the next part of the build.

Imagine forgetting to remove the cable-ties 😅 I don't think it's possible but I've seen a lot!

So I skipped a really big part, but I just simply can't record that progress I needed both hand and I needed to work fast.

What I did here was I heated up the bearing in the mid plate, made it real warm but not too warm as to temper the metal. Then I grabbed the combination of shafts that I cable-tied together and pulled it through the bearing. If taking too long the main-shaft will only go through halfway and then you'd have to press it all out again. It can be a real pain in the ass.

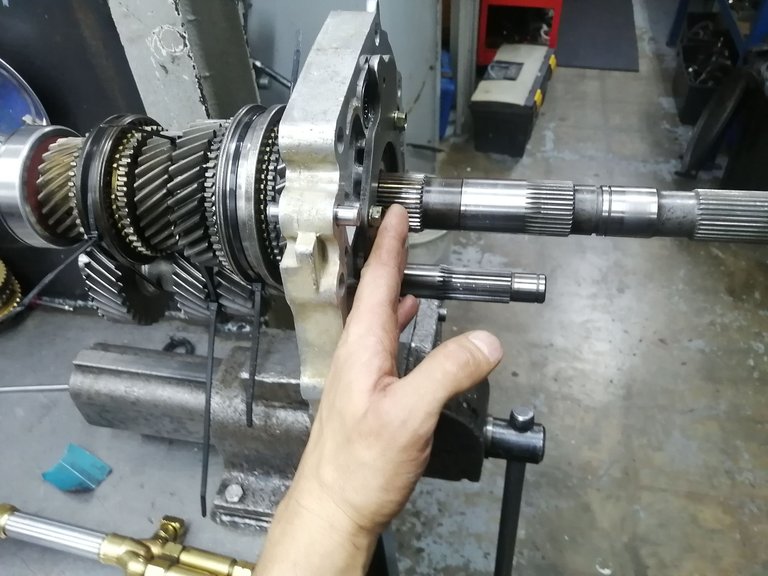

Adding 5th And Reverse Gears

Now this is probably the most tricky part, it has a lot of bushes that needs heating up and pressing over, much like the main-shaft that needs to be pulled through the warm bearing.

But these bushes can absolutely not be tempered, they need just the right amount of heat to push over but not too little as to not go through all the way. Like I said you'd have to press it all out again and as I mentioned at the start of this post it's a crappy transmission to tear down.

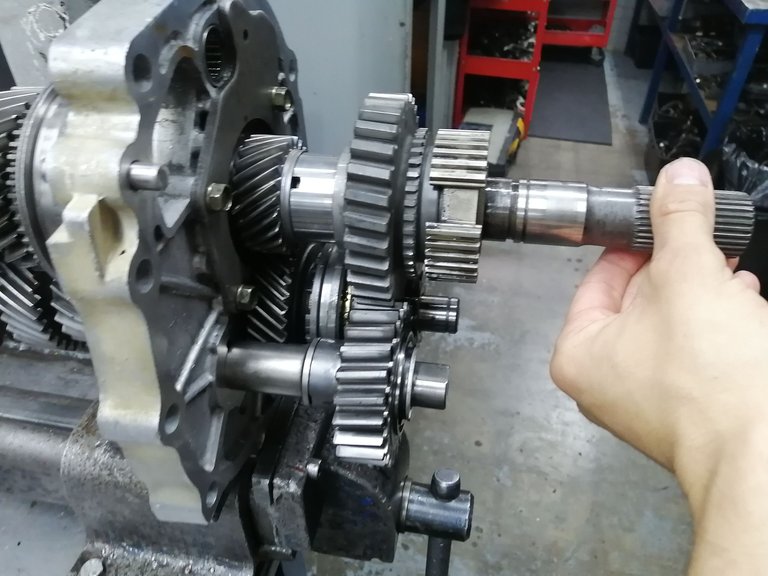

5th and reverse gear added, now it's mostly the casings remaining.

Final Pieces To Fall In Place

Okay so I didn't get photos of where I fitted the gear selectors along with the gear selecting shafts and that was actually a big part of this build. Meh sorry folks, nothing I can do about it now.

It does look a lot more bulky with the gear selectors added actually, doesn't look naked and thin anymore.

Once the casing is fitted over the input-shaft I need to install the bearing in the lower left corner of the photo before adding the front cover onto the bell-housing. A simple step but easily forgotten!

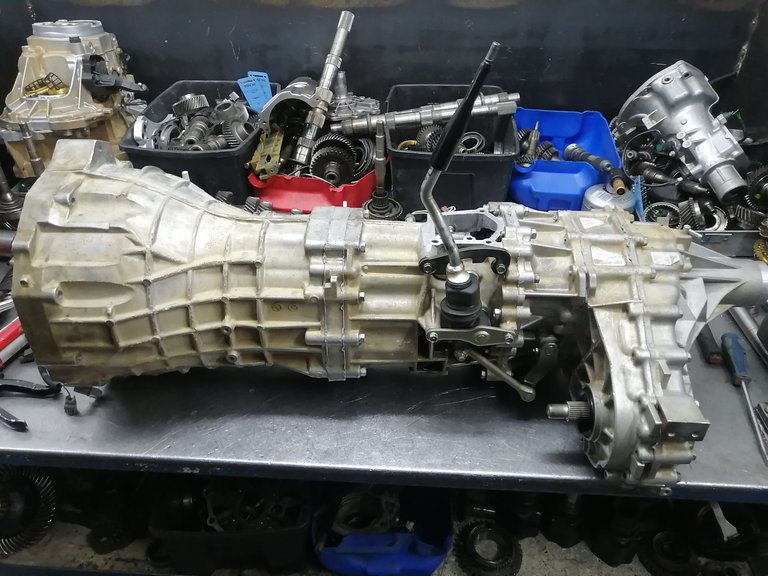

Transmission with it's casing fitted into place, both the front end and back end. The 4x4 gearlever is also added.

Remember in a previous post of mine I rebuilt the transfer case for this transmission. Well now I've got to add it all together and finish the puzzle for good!

Well shite! It ain't so small anymore is it now. 😅 I just checked out the photos of where I cable-tied the counter-shaft to the main-shaft and thought wow it does look small but they are actually big, the photos are misleading.

Connecting the people of #HIVE across South Africa. #hive