Hi all hive friends ❤❤

On this very sunny day, I visited my old friend at his work place. He worked as a brick maker in his village. He has worked as a brick maker for a long time. I visited him because my friend doesn't have time to travel because he is a hard worker. So I took the initiative to go directly to where he worked.

When I got there I was greeted like a special guest, he was a good friend, and after chatting for a while I asked him to tell me a little about brick making.

So my friend said, the first step in making bricks is that we have to have the materials first, that's the most important thing. And we have to choose the right soil. Then it is molded to the size of a regular brick, after that it goes to the drying stage, then directly to the firing stage. After the firing stage, good bricks are selected to be ready for sale to consumers.

OK, all my friends. I will share the stages of the stone making process that I managed to photograph and study and this has become knowledge for all my friends here.

Because the workers who printed the bricks have gone home, I can't share pictures of how to print bricks. So let's go straight to the brick drying stage.

Drying stage

After the bricks are printed. Then the bricks are arranged neatly in the space provided. And this is what is called the brick drying stage. These bricks are deliberately laid out here for several days so that the bricks dry naturally.

And we could see for ourselves that the bricks were still wet and the ground was still very soft. And I also held one brick to make sure, and it was true that the brick was still very soft.

And after the bricks are dry, then the bricks are burned. And here I also took several pictures of the brick kiln

Combustion stage

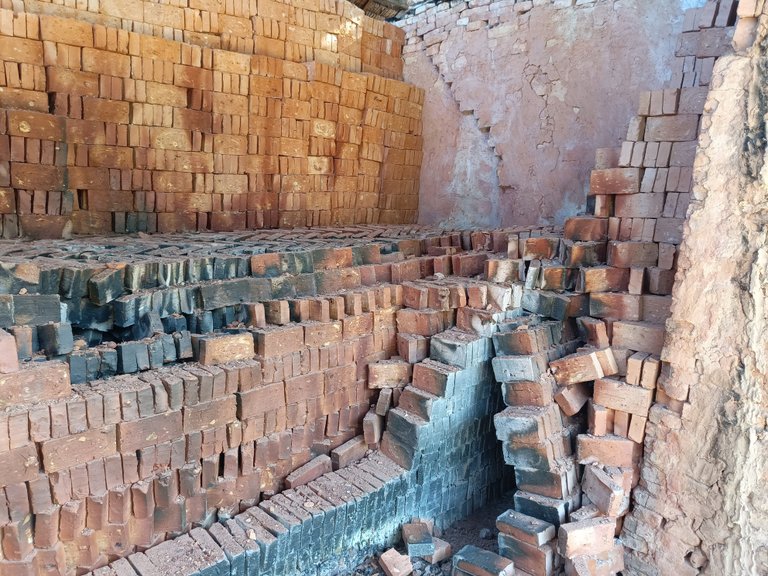

This firing stage is carried out so that the bricks become strong and durable. Usually the brick burning process takes up to a week or more, depending on the brick. After the firing is done correctly, the bricks are waited until they cool and enter the final stage, namely selecting good bricks to sell to consumers.

I don't understand the complete process of making bricks, some of the pictures and knowledge that I share are knowledge that I know from my friends.

And these are the bricks after the firing stage.

These are bricks that are ready to be sold, perhaps because the quality of the bricks is not good, the bricks are placed separately from the good bricks. because the good bricks were sold out so I couldn't take photos.

And of course you are wondering, what material is used as the main ingredient to light the fire for the brick burning process which takes days.

The main ingredient used as a fire source is palm fruit dregs. This dregs is very strong and lasts a long time when burned, resulting in a fire that burns for quite a long time.So there is no need to spend money to buy wood as the main material for fire, because the dregs from palm oil are free and not for sale.

After I got a little explanation about the process of making bricks, I thanked my friend, because this knowledge could broaden my insight. and I share this knowledge here for all my friends ❤

Note :: Nothing is impossible in this world. It depends on whether we want to try it or not. Because in reality, all humans don't know anything when they are just born into this world, everything requires a process to produce satisfactory results.

Here are some pictures and a little input from me today, I hope you enjoy it. Take the positive side and throw away the negative side. I apologize if there are errors in conveying words and sentences, I am a human being who is not free from mistakes.

Images and stories are purely mine, I did not plagiarize anything from other people's content. I took the picture using an Infinix 10 Pro cellphone and edited the image using the Lightroom application.

And I wrote the article above in Indonesian and translated it into English with the help of Google.

I'm @riyat. See you again in my next post❤❤

Published with Ecency