Drilling through tiles. Risky business, made even more so by the wife's reaction if I'd dared to crack one. But disabled handrails don't attach themselves, so after some deep research on YouTube, an order for some cheap 'diamond' hole cutters from China and a deep breath, I brought my 'A' game to the table and went for it.

This is what I learned...

Firstly, you cannot use regular twist drill bits or carbide tipped masonry bits to drill through ceramic or porcelain tiles, they're just too hard and brittle and will crack. If that happens, it's a big problem as you have to hope you have a spare and then start chiselling the thing off the wall and it's a nightmare.

You can get specialist tile bits where the end is shaped a bit like a spear but my experience of using one of these is not great and As I needed quite a large hole, I didn't fancy it.

On doing some research, I came across these diamond-tipped hole cutters and saw a couple of videos of them being used to make holes in tiles so I went on Shopee, full of trepidation at the cost to find some Chinese imports for less than 5 quid for a pack of 5 different sizes. Probably too good to be true, it was worth a shot and they turned up from China in about a week. So far so good.

Here they are. Very nice looking things in various sizes but quite short in length. Bargain at £5 GBP, $7 USD. I'm thinking they might not be real diamond at that price!

Last week, despite suffering from a very mild, but very annoyingly long-lasting dose of Covid, we drove down to Samui to get a few jobs done as we'd had to cancel all our cases for the week and first on the list was the disabled rail for the bathroom. It needs to be firmly attached as it has to carry the weight of someone using it to lever themselves up from a wheelchair onto the bog.

The first thing to do was to mark out the screw holes and the location and yes, I did use a spirit-level to get it straight. I drew in the holes in permanent red marker as I wanted it to stick and show through after I covered the location with a piece of masking tape, just to get a little grip and avoid slippage.

TOP TIP

DON'T SET YOUR DRILL ON HAMMER SETTING!!!

Very important. You don't want it battering away at the tile, let the drill bit do the work.

The first small problem I came across was that as I was drilling in horizontally, the bit kept slipping, even with the tap so I got around this by starting at a very steep angle to the tile and using the bit to cut in before straightening the drill up level. Worked a treat!

Start it off on an angle at a full speed! Keep a spray bottle of water handy to keep the bit cool as it gets very hot, very quickly!

The other cool thing about these drill bits was they were marked to accurately gauge the depth of the hole.

Another thing to remember is not to push too hard, when the bit gets through the tile itself, it eats the brick or concrete behind and the chuck will smash into the tile, ruining all your hard work. I actually used a standard 1mm smaller, masonry bit to finish the rest of the hole after I'd got through the tile.

Here we see four holes drilled with the supplied rawl plugs inserted into the holes. See the first hole I drilled where it had slipped a little? I also pushed these plugs deeper into the hole as I wanted them to grip masonry, not apply pressure to the tile itself.

Attach the plate, screw up the four, pretty hefty screws and job's a good 'un!

So the only thing left was to wire in the emergency alarm cord and that's it for the bathroom. One more job ticked off the list.

As for the other completed jobs...

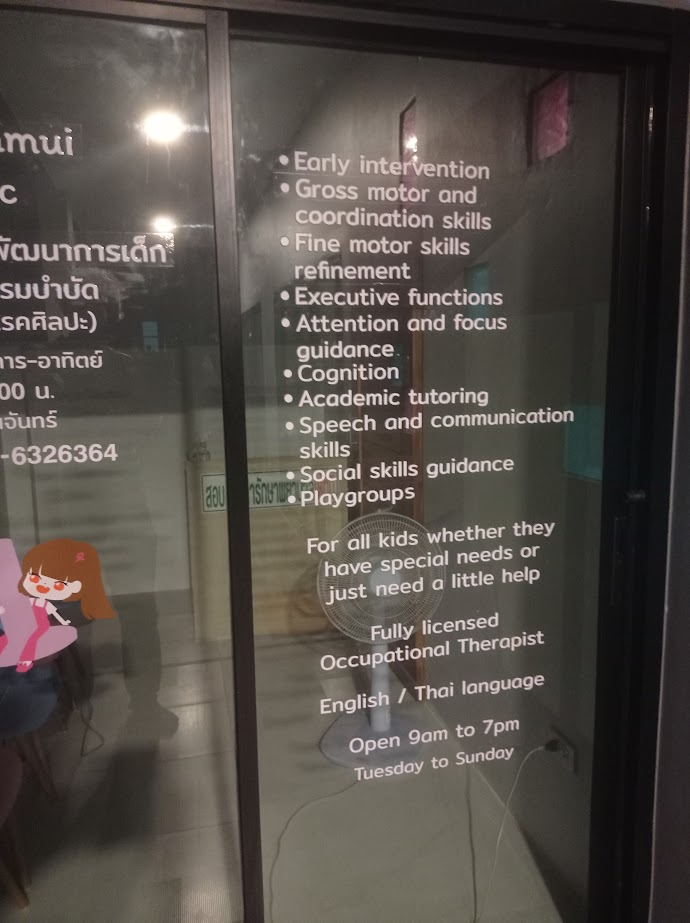

All the padding for the playroom had arrived so I fixed that to the walls and then it was on to the lettering for the door! What a royal ball ache that was to get straight. Next trip, I need to rip a bit of the ceiling out to access the steel beam I had put across to be able to hang off the required swings. I'm not fancying that but I have got a few weeks to 'think' about it until we go down again!

Using a marker pen, I had to draw a huge grid to the rear of the glass to be able to stick the lettering, one line at a time to the front of the glass. It took ages to get it right but at least it's straight and central!

Luckily, the printer had written all the spacing sizes down so it was just left to me to draw the lines accurately and straight! "Take your time." he said, He didn't say quite how much time it would take though.

It didn't come out too badly and most important, no spelling mistakes!

So that was it for another trip and we did the 750km drive back to Bangkok, bringing our Covid back with us and hopefully having not shared it with the in-laws!

Thanks for reading, best wishes to all!