Hello once again…

Hoping you all are in great shape and condition as you read through this article.

This day I will be sharing with you one of the overhauling job in one of the machineries onboard that we did just the other day.

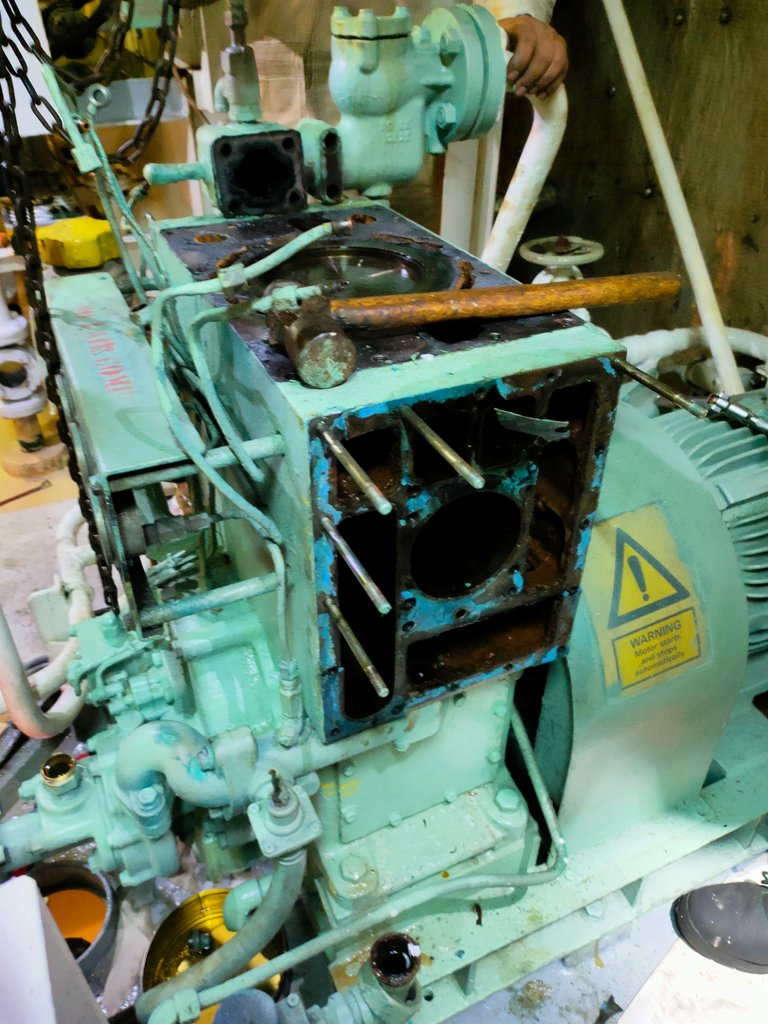

This machinery is the ship’s main air compressor. We observed signs of blow-by from the breather cap which means the piston rings need replacement as the compressed air is passing through it. The air passing from the piston rings go through the crankcase which in turn pressurizes it. An oil vapor or oil mist will be seen exiting from the breather cap and traces of oil adhered in machinery casing and accumulating in the flooring will be observed during this phenomena and if this goes on for quite a long time, we will have an unnecessary excessive oil lube oil consumption which is not ideal.

We removed all pipe fittings, air valves, inter and aftercooler, and the piston.

We inspected all the machinery parts that was removed, cleaned the machinery casing and replaced pieces that needed replacements like the piston rings and several gaskets. After a thorough inspection the removed parts were assembled, filled the crankcase with oil and the cooling water was supplied. The air compressor was tested afterwards. The parameters like air pressure, cooling water pressure ad oil pressure needs to be checked when the machinery was being tested. If they were to indicate normal operating parameters and the machinery is running stable, it means the task was carried-out correctly and nothing is missed.

The one doing the maintenance in the photo are our junior engine officers and ratings while we senior officers are just standing adjacent the area for supervision. They needed supervision in order to ensure that the task will be carried-out in a correct manner.

That is all I wanted to share with you today. Will be sharing again with you when and if any major overhauling job is carried-out in the coming days.

Thank you for reading