Over the last couple of years I have changed how I get my coffee fix. Once I used to mostly go to a big store to get my daily fix, but now I am making it at home. Here is one of my recent espresso machine rebuild and repairs.

First and foremost this machine is duel branded between Bezzera and Pasquini. The parts are interchangeable but Pasquini Livia 90 is more common and widely known.

A little about me, I enjoy tinkering on things and thought this would be a good project for me to see if I could bring an old machine back to great working conditions.

Where I got the machine was from someone cleaning out a storage unit, he had some sort of restaurant supply business at some point and explained to me that the machine was in working order and that it was used briefly but then stored for many years. The price was good for a machine that had these conditions but I knew that there was a very good chance that this machine would need some decent work. Little did I know that it would involve doing a full tear down of the machine.

Lets start with why I felt this machine would be a good one to work on. The specs on this machine showed me that it would produce a high quality almost professional espresso shop. This machine was manufactured in 1999 and at the time was known as a prosumer machine. This would be a great machine for myself and if it would work properly would last me many years to come. It is a manual machine meaning that you will push the button to start and stop the shot of espresso.

On the visual inspection of the machine it would require a new group head gasket, a water pump, and a water reservoir. The water reservoir came out to 71 USD and the Water pump was roughly 30 dollars. Not bad because the parts all showed up with in one weeks time.

The group head gasket became another issue. All the information that I found online was pointing me to getting a standard gasket for the group head, these are known as E61's and after I got the replacement gasket I find out that I had an old group head, but they had one from a used machine that would be ok to swap out. There goes another 130 USD, for the new group head, shower screen, and gasket. But now I have the correct parts and am ready to get this machine working, or so I think.

It is now assembled new parts are installed, and I am finally ready to pull my first shot on this machine that has not seen the light of day in over 10 years. I turn the machine on and everything seems to be working fine. I make my first shot and THE MACHINE IS ALIVE! I am excited to have the machine working again. I wanted at this time to do a clean on the machine and make sure that the steam is working well, I check that off the list strong steam coming from the machine. I go to turn on the hot water and NOTHING! absolutely NOTHING is coming from the hot water side. Hey at this point I can still make espresso shots and steam milk so I am claiming victory on the machine.

After using The machine for a week I notice the quality of espresso being made is not of the highest quality, and there is a faint hiss coming from inside the machine. I decide to do a back flush on the machine and this makes the faint his much more noticeable. What could this issue be?

The line from the boiler to the 3-way solenoid valve developed a crack not in the copper pipe but in the brass fitting and was making it to where the pressure was not able to reach all the way to the group head. I now feel defeated in this process. The two options are to find a new coper line or get the existing one re-brazed. It turns out that the replacement part was 18 dollars so a new one is now on the machine.

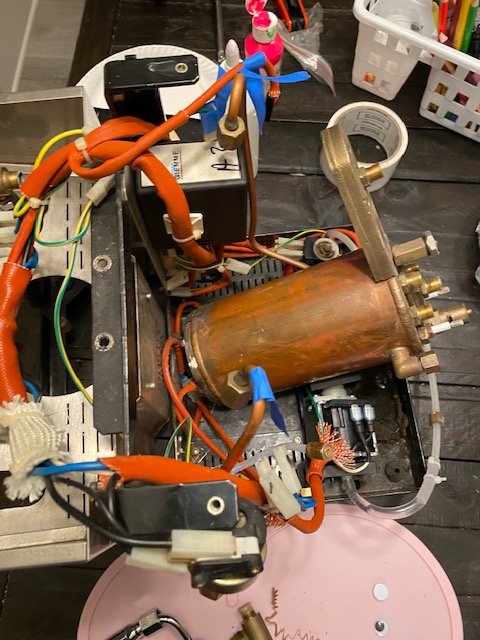

Now with the machine fully apart I am determined to figure out why the hot water is not working on the machine. Given the long time in storage and the other gaskets that needed to be replaced it was time to also replace the gasket to the boiler and do a inspection on the internals of the boiler. I am glad that I did this.

This machine NEEDED a good descaling. Circled in red is the reason for the hot water to not work, calcium build up completely clogged the hot water tube. The heater core needed the descale just as much.

Here is the descale bath.

After everything is cleaned up I move on the the reassembly, I am hoping that no further issues will arise with working on this machine.

Once assembled, I turn on the machine and everything is working great! Hot water is working again, the steam is even more powerful than before and the espresso shots are with great crema' again! This machine is now ready for many more years of use.

The one positive to having to do a full rebuild on this machine is that I will know how to make future repairs with confidence. I was intimidated when I first started on this project but I am thankful to know how to work on something I plan on keeping.