This week has been so hectic and we are only on Wednesday guaranteeing we are going to be tested some more this week and then next week. It is only during these busy peak periods do you find out if your systems that have been put in place actually work. Up until now nothing has been really tested and that includes the staff.

I should be in the warehouse today, but instead find myself running around sourcing items that frustratingly have run out or a special hard to find fuse/chip has blown. That was yesterday and it took just on 6 hours to find one for the sealing machine and had nearly given up and was about to buy another machine. One of the places I had been visiting in my quest earlier in the day found one and phoned me to come collect.

The scale we weigh our products on blew on Sunday and had to have that replaced on Monday. I blame load shedding for this as the warehouse is still being affected at least twice per day. Like most guys shopping the actual purchase took less than 2 minutes as it is a must have item. The less buttons the better as my staff members have less to fiddle with and the less likely hood of breaking it. Indestructible items are not safe here and they will find a weak spot somewhere.

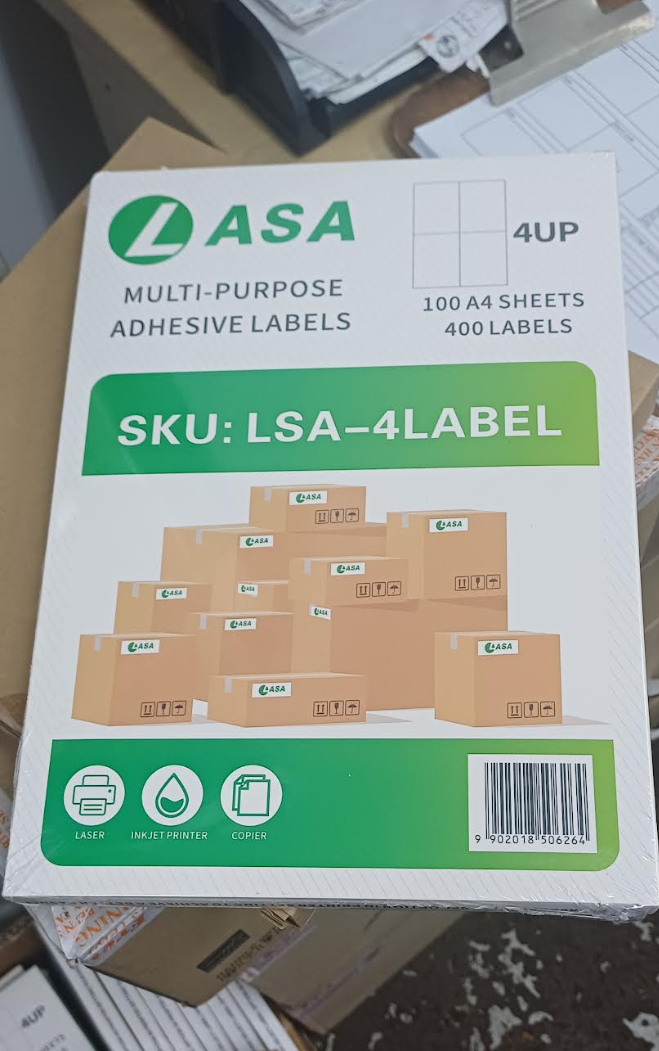

Today my quest was labels which we normally get direct from LASA and they are now out of stock until the end of January. This tells me they are imported and you have to wonder what is actually made locally anymore? These are all business ideas if anyone is interested because every country is in the same position and this is not a problem unique to South Africa.

I will finish finding these tomorrow and have a few contacts that I have not hit up yet. I get it that everyone is busy, but at the same time you cannot take your eye of things you use daily. It is like toilet paper you may run out once ,but you will never do it again.

There are things in place so run outs do not happen in my areas so others need to do the same. The outer casing for packaging ran out this morning and the replacement stock is ready for collection. I was told they had started the last roll on Sunday so I had been informed. Somehow I think it was already being used before that as this roll lasts about 2 weeks so only lasting 3 days does not add up.

My supplier is the same person who I helped stake COTI so having close relationships does help jump the queue and help solve unforeseen problems. Getting this outer casing sleeve made within 24 hours would not have happened otherwise and would normally take over a week as tis is a custom size and not a stock item.

Who knows what crisis will appear tomorrow and this is a case of putting out fires as they appear. Next season will be better than the current as we are still learning on the job.

Posted Using InLeo Alpha