Bzzz!

When there is no money to buy a finished product, or when prices for niche goods go up during the season, you have to get out in such ways...

In one of the previous publications, I showed the repair of a makeshift storage for irrigation water, but when it was filled with water, a leak was discovered.

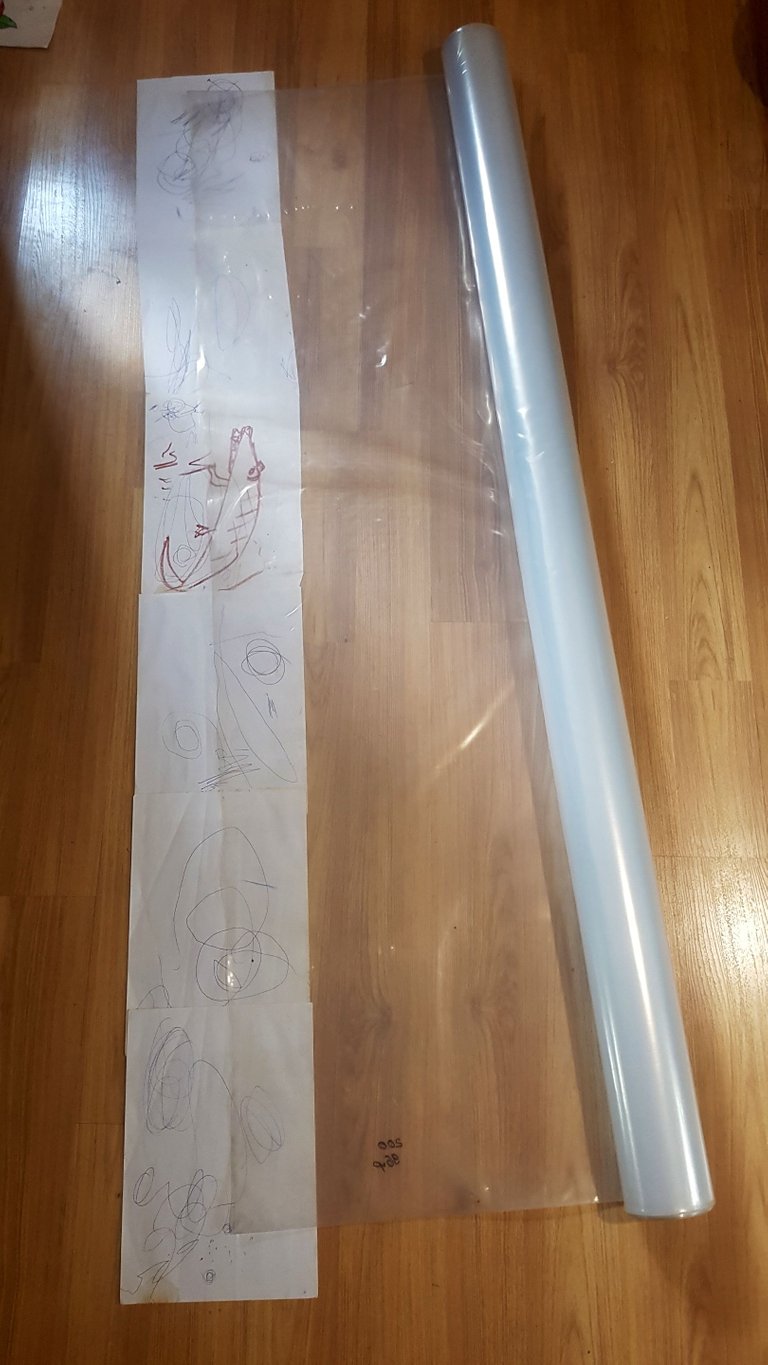

It was decided to make a new bag for water storage from a polyethylene sleeve instead of last year's leaky one, and even materials were purchased.

Because of the wet weather, I didn't have the urgency to water the garden, so I wasn't in a big hurry to make it. But don't delay any further, it's time to get down to business.

How to solder a polyethylene sleeve without damaging the iron.

Step-by-step instruction:

To begin with, we will prepare the surface where we will do the work so that it is convenient to place the roll and unwind the edge of the sleeve

Then we put plain paper under the edge of the sleeve. I recommend using a baking sleeve, but old drafts will do.

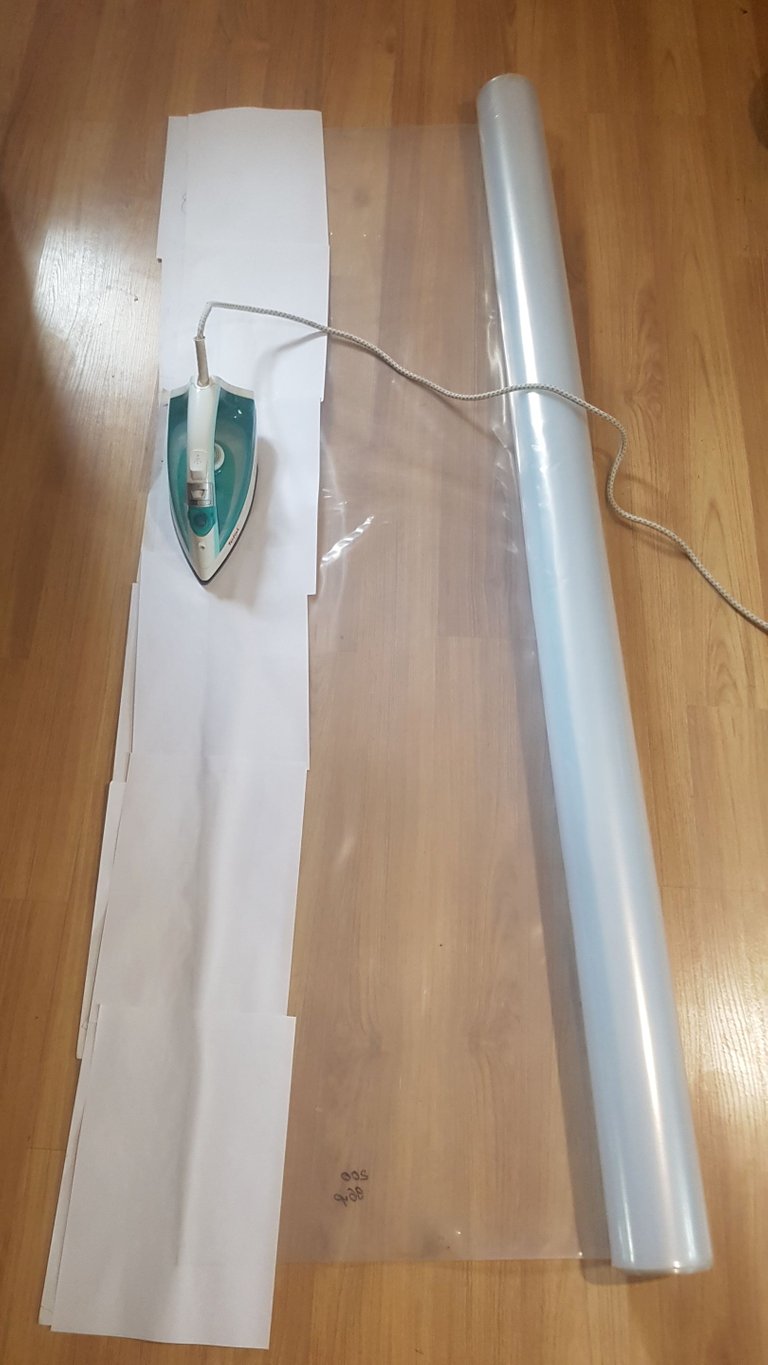

In the same way, we lay a layer of paper on top.

This prevents the polyethylene from sticking to the hot iron.

When using drafts, make sure that the text on the sheet of paper is located on the reverse side of the ironing surface, otherwise there is a risk that the ink will smear the soleplate of your iron. (Clean sheet surface out!)

By this stage, we need an iron heated to the maximum temperature.

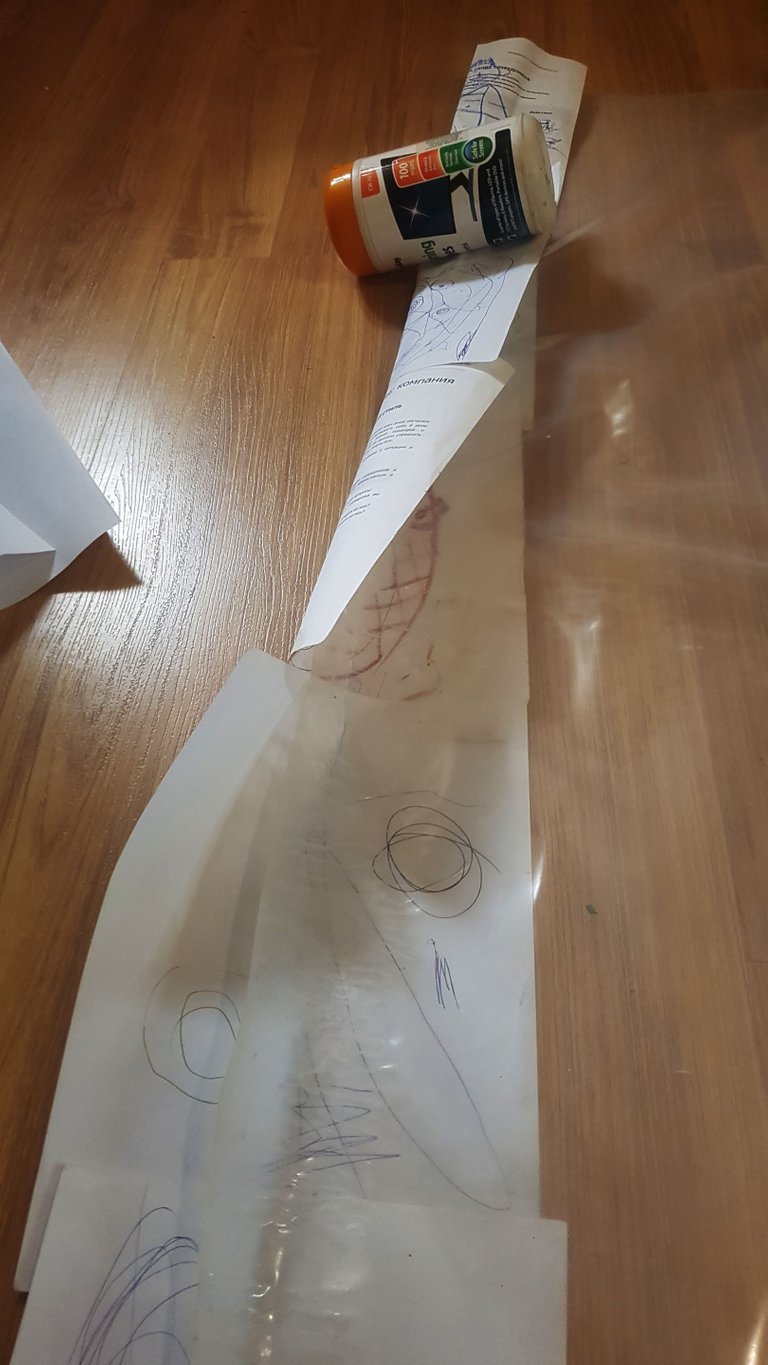

Ironing the edge of the sleeve with a hot iron, we solder two layers of polyethylene together

Iron carefully and slowly so that the polyethylene warms up well through the paper and fuses together.

Having removed the paper, we will see such a sealed edge.

We carefully check it for the absence of marriage.

This edge was not heated enough, it's good that we checked our work before we filled the bag with water)))

For reliability, I decided to bend the edge of the bag and warm it up again!

I decided to bend the edge of the sleeve along with the sheet of paper on which it was lying and did not notice that I was ironing the paper directly over the ink from the printer ...

How to clean the soleplate of the iron from laser toner will be in the next issues)))

As a result, we have a solid reliable thick seam.

Can be tested for leaks...

We place the bag in our frame and go turn on the pump.

Water begins to flow, after a while we will come to check

After some time, the container was filled to the brim.

A day later, I came and made sure that the water level remained in place and everything around was dry.

It is done. Now my work on watering the beds of the garden will be greatly simplified.