Good day to my friends on Hive and especially to the Fixologists of the DIY Hub! My name is Zak Ludick and I am writing to you from Cape Town, South Africa.

These days it is very easy and simple for people to throw away broken items, counting the cost of the item against the cost of time and convenience.

But this is also a costly attitude that is wasteful of the resources of the planet and economy and thus bad for the environment. Instead of counting the cost in money, counting the cost in something greater than ourselves is more important!

The disposable mindset is also the opposite of learning core trade skills for ourselves. I learn and cultivate my ability with tools with every project I take.

More so, I had my 12 year old watch the process and explained to @merenludick what I was doing, every step of the way. Thus, skill transfer is in progress!

Sometimes I give my son a task to do that I could have done on my own faster, but instead coach him through it. Because of this, Meren has learned a lot of skills!

Today's Repair - Bent handle on a 3/4" Pipe Bender

Now, you might ask how someone bends a pipe bender! These pipe benders are used to bend soft drawn copper piping. There is actually no way of bending the handle in normal operation unless the guys were using this to bend steel pipe or if there was previous damage.

Either way, the office looked at the handle and said it was beyond repair, as it cannot be bent back into position.

Not so for the Fixologist!

I told the office I would fix it and took it home and fixed it that evening and returned it the next day. This is how I did it!

The bent part won't be able to bend back so I cut it off with the grinder.

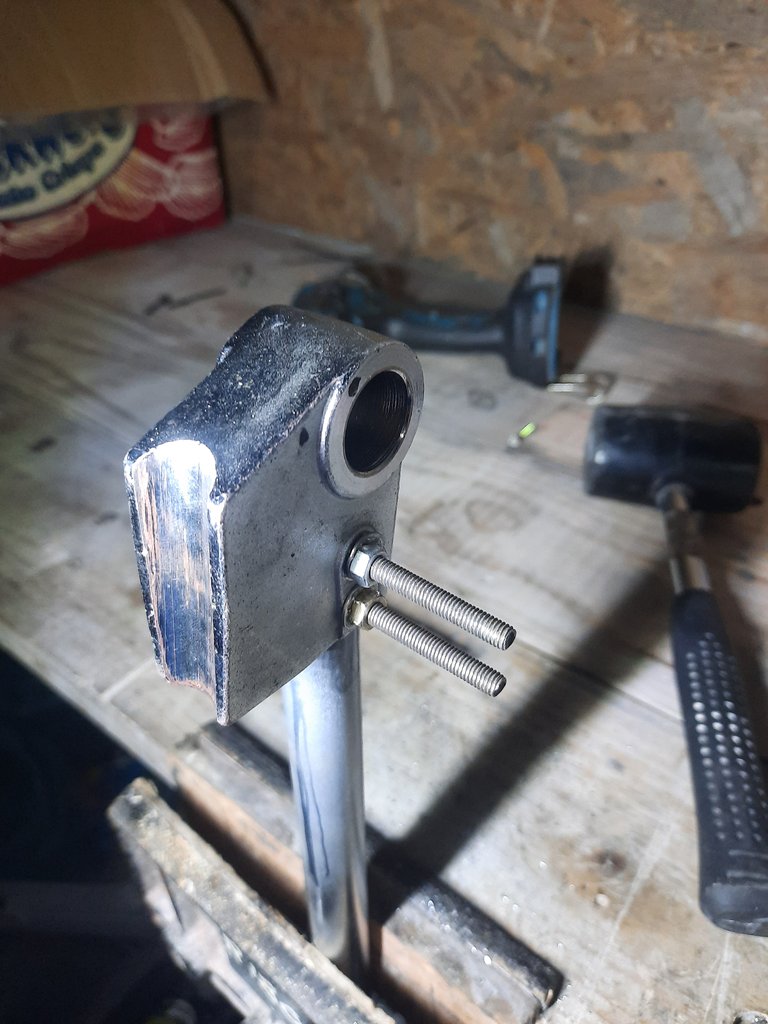

I then had to separate the bent stub and the head piece that connects to the rest of the tool. The manufacturer of the tool had used some sort of punch to lock them together. So all I had to do was drill them out, while fully intending to replace that assembly with bolts.

I selected some bolts of the right diameter and some washers. I ended up using the star washers to give those nuts grip.

The shaft did not fit into the head straight away, it needed some sanding with a flap disc to smooth it out and get it all the way in. Using a permanent market during steps ensures that you keep track of where to grid.

Once the pipe was sunk deep enough I drilled through both holes to the other side and stuck my bolts through, then tightened it up.

I then cut the bolts off shorter as well.

And there you have it, this piece was successfully repaired and we only lost about 3-4" of handle length.

The handle was reunited with the rest of the tool the next morning...

Everything seemed to line up well.

Side by side with another Pipe Bender. New, they go for around R875 or $51.

The company had decided on buying a new one even after I told them I will fix it, so now we have two.

Until next time.

Cheers!

@zakludick