Hi,dear HIVErs.

Programming toolpaths for this piece was extremely stressfull since it takes alot of CPU and RAM power.

As far as i know this piece is used as a tool for spine surgery and it is a prototype.

Production cost of both pieces is roughly 1500euros.

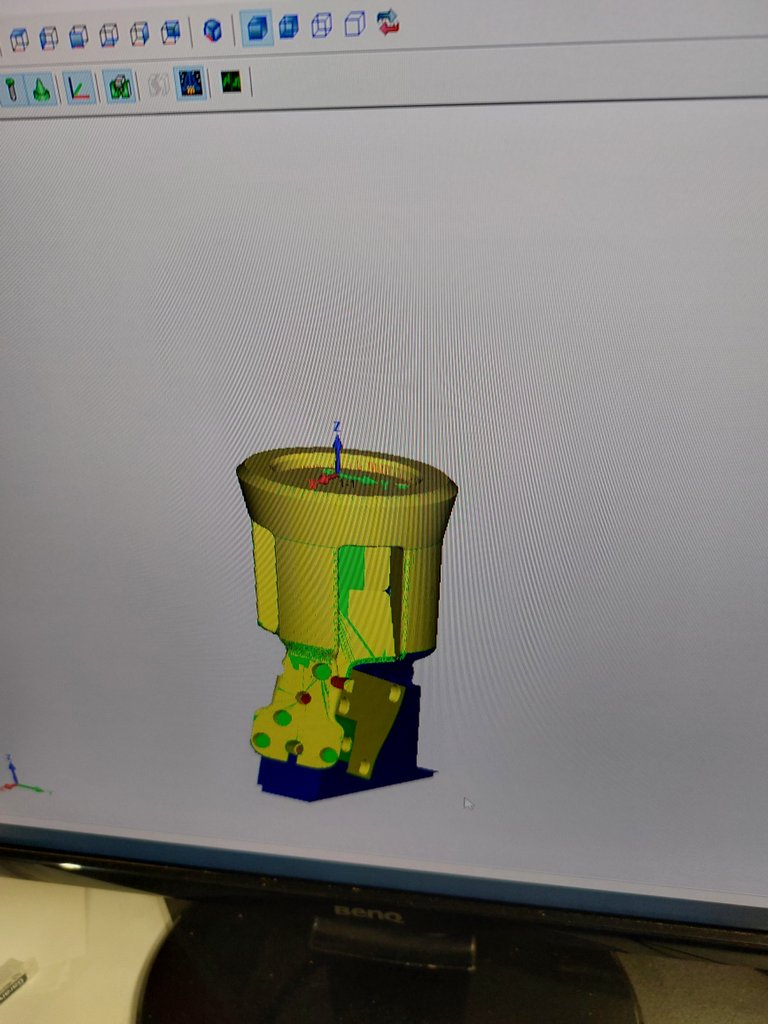

The first picture shows a 3D model i get ao i can start working.This next one is when i run the simulation after i completed the tool pathing.

Various colors indicate if the piece is within designated tolerances.Green and yellow is fine,blue is if it hasnt been touched at all and red is if it is overmilled or a crash has occured.

The toolpath creation took about 12h.

We had to mill 2 pieces which took about 5h each.

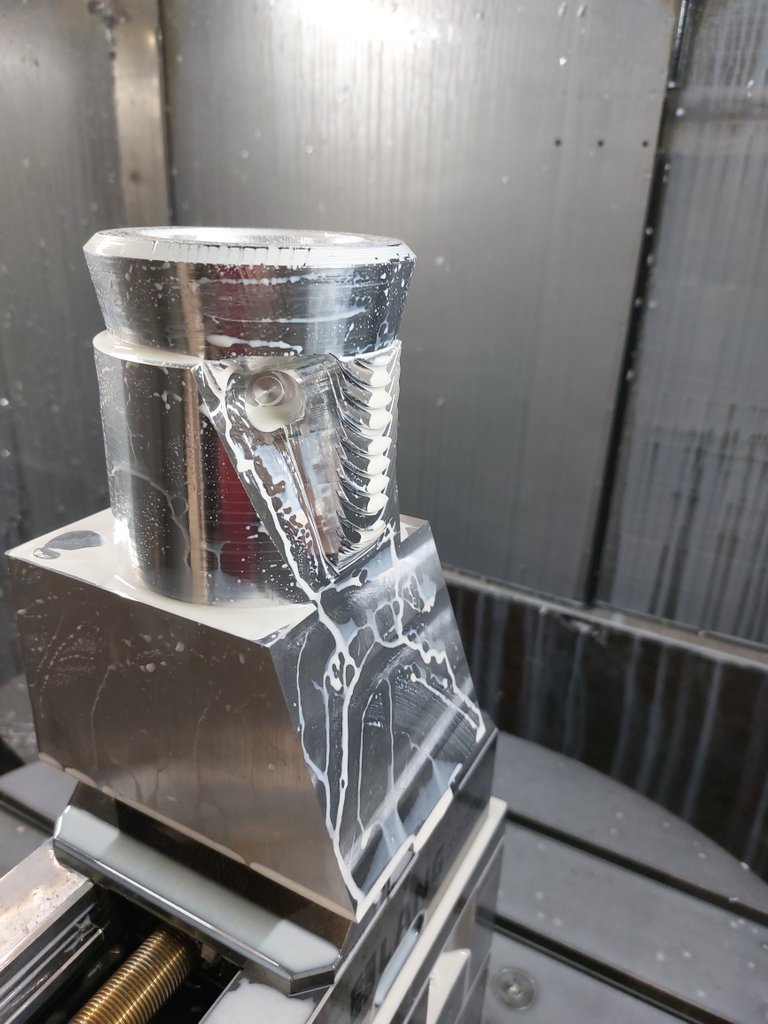

Here we have the workpiece mounted in the vice of a 5axis machine.

Few operations later:

After about 2h:

We still had some minor details to work out but i was not able to document it,i was already at work for 12h and let my coworker finish the job alone.He is a good CNC operator and i put my trust in him.

Next day when i showed up at work the first thing i checked was if the pieces were finished,and i was happily surprised.

It was ober and there were no mistakes on my or the operators side.

We still have to hard anodize it but as far as manufacturing goes,we are finished.

This is the final product.

Thank you for reading.

Have a great work week.

CYA