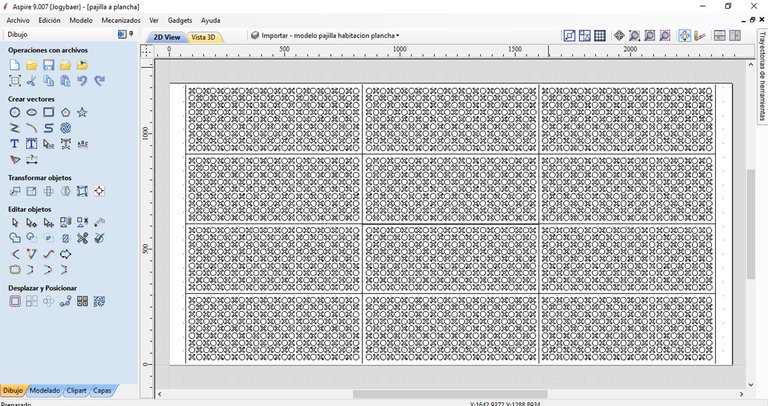

Hello my hardworking and fun people of this community! This time I want to share with you the construction process of a decoration piece that several colleagues are working on. I am doing the drawing, digitizing and processing of the main and most complicated part of this piece.

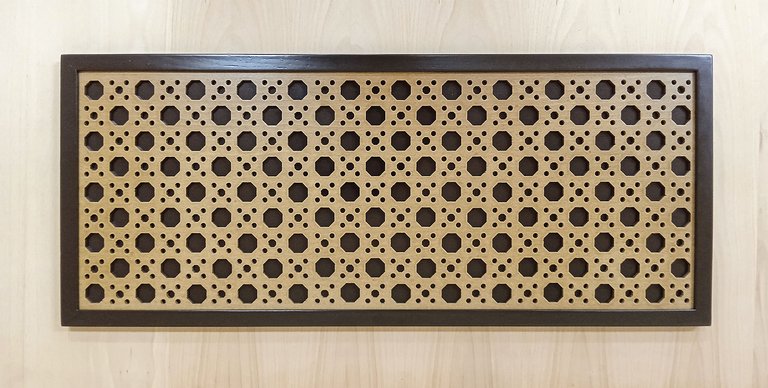

In one of the previous posts I told you that I had a friend with a very well equipped carpentry, so I am collaborating with him in the realization of these decorative elements. It is a celocía (a pattern with a certain design cut in a material) in MDF board laminated in wood on both sides.

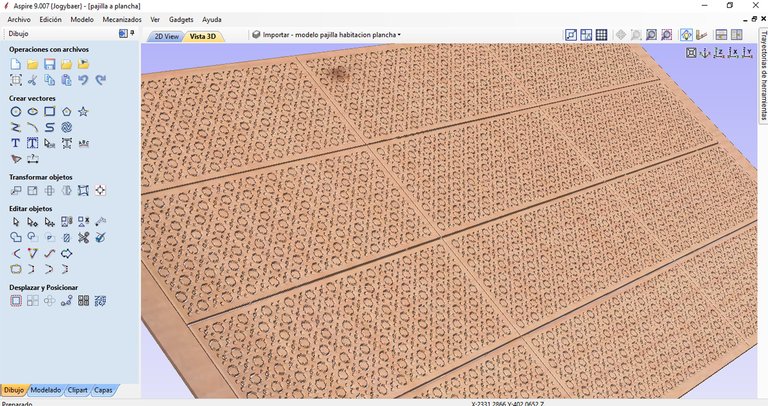

This process is carried out in a CNC router (machine controlled by a computer whose function is to make cuts in an automated way) for wood in this case. This machine has 3 axes where the motor that holds the milling cutter slides, X, Y and Z. It is a fully computerized system that performs very precise cuts and engravings. It can also process other materials such as PVC, methacrylate, plastic and even thin sheets of soft metals such as aluminum.

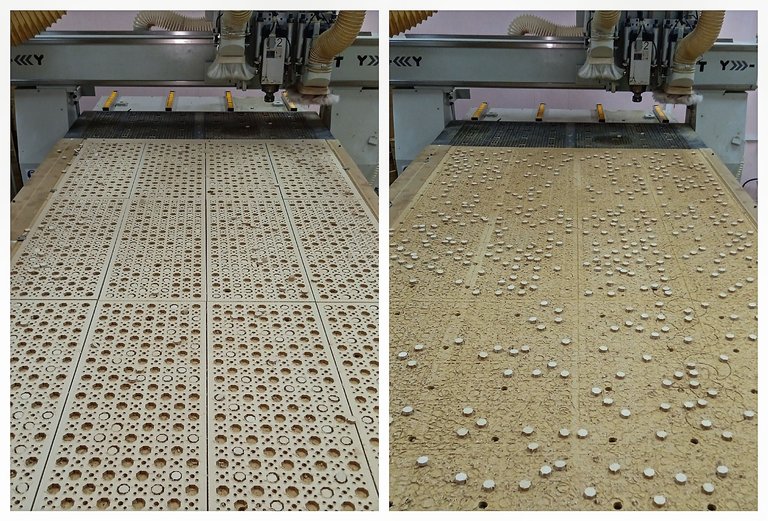

Once the design is digitized, it is digitally modeled in the CNC's native software. After the pertinent adjustments have been made, the milling order is executed and ... that's when the dreadful noise of automated cutting begins, that's why this type of machine must be isolated for both sound and waste (it has a chip and dust extractor system).

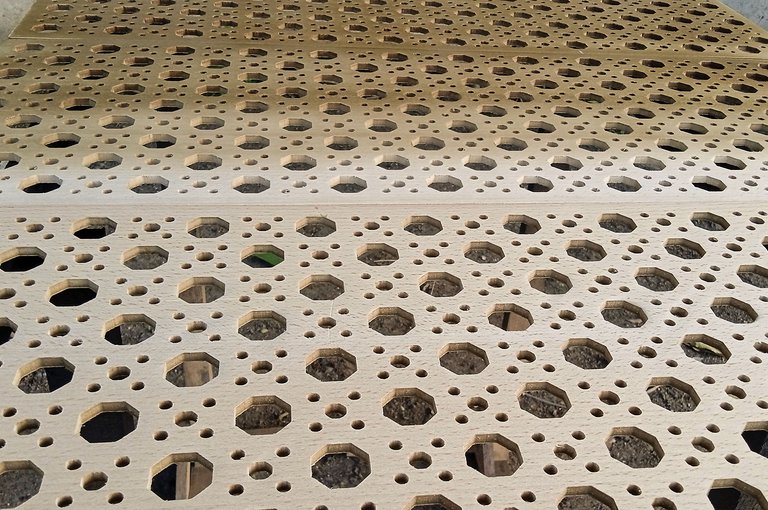

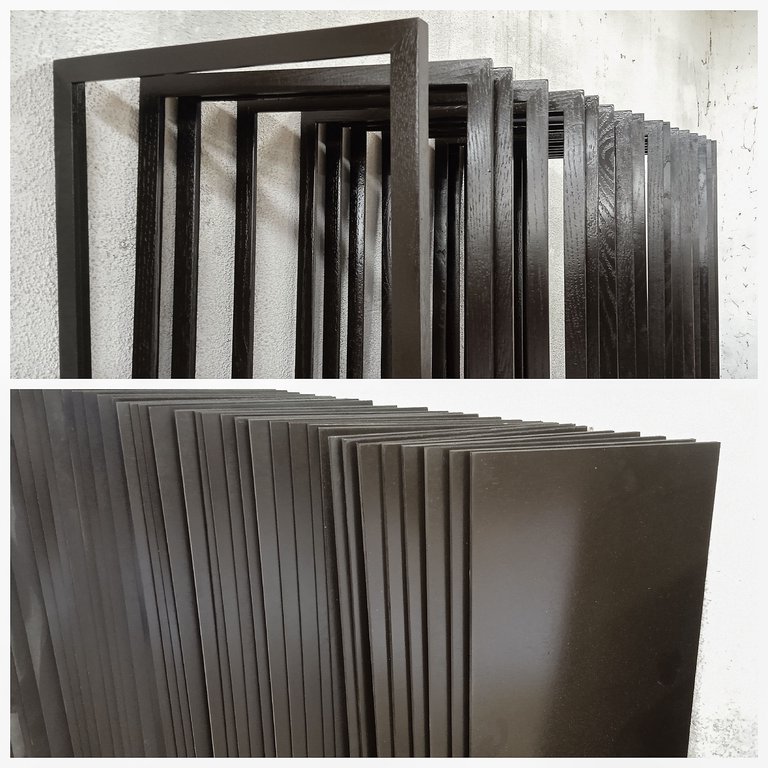

As the piece is made of wood, it is always necessary to prepare it very well for varnish or paint, which implies an intense sanding. This element includes a wooden frame that is also built in the carpentry shop.

After the proper preparation of the pieces, the final stage is the finishing, with paint and varnish.

This is how it looks at the end of the process.

I wanted to present this work because I find it interesting and maybe some of you do not know how it is done.

I await your most sincere opinion or advice on this post, comment me if you wish, I will answer you without fail.

! [Spanish here]

¡Hola mi gente trabajadora y divertida de esta comunidad! En esta ocasión quiero compartir con ustedes el proceso de construcción de una pieza de decoración en la que estamos trabajando varios colegas. Yo estoy realizando el dibujo, digitalización y procesado de la parte principal y más complicada de esta pieza. En uno de los post anteriores comenté que tenía un amigo con una carpintería muy bien equipada, pues le estoy colaborando en la realización de estos elementos decorativos. Se trata de una celocía (un patrón con un diseño determinado calado en un material) en tablero de MDF laminado en madera por ambas caras.

Este proceso se lleva a cabo en un router CNC (máquina controlada por una computadora que su función es realizar cortes de forma automatizada) para madera en este caso. Esta máquina tiene 3 ejes por dónde se desliza el motor que sostiene la fresa, X, Y y Z. Es un sistema totalmente computarizado que realiza cortes y grabados muy precisos. También puede procesar otros materiales como PVC, metacrilato, plástico y hasta planchas delgadas de metales suaves como el aluminio.

Una vez digitalizado el diseño se procede al modelado digital en el software nativo del CNC. Después de realizado los ajustes pertinentes se ejecuta la orden de frezado y ... ahí comienza el espantoso ruido del corte automatizado, por eso este tipo de aparato debe aislarse tanto para sonido como para el desecho (cuenta con un sistema extractor de virutas y polvo). Cómo la pieza es en madera siempre hay que prepararla muy bien para el barniz o pintura, eso implica un intenso lijado. Este elemento contempla un marco de madera que también se construye en la carpintería.

Después del adecuado preparado de las piezas se pasa a la etapa final: el acabado, con pintura y barniz.

Así queda al final del proceso.

Quise presentarles este trabajo porque me parece interesante y puede que alguno de ustedes no conozca como se hace.

Espero tu más sincera opinión o consejo sobre este post, coméntame si lo deseas, te responderé sin falta.

Both the photographs and the text are of my authorship. Translated by DeepL, since my native language is Spanish.