When 3d Printers started to take off for the home market it was mainly nerds and geeks who first got them. Back in those early days, you needed to be a nerd to get it working and usually, you would spend most of your time trying to get the damn thing to function properly, seeing as most came in a kit form.

Now, there are many on the market and if you can assemble Ikea furniture there is a good chance you will be up and running in no time. Printers are getting more plug-and-play with every version and there are many manufacturers and price ranges to choose from. It is no longer rocket science. But now you have it turned on, what can you use it for? This was me when I first got mine.

Luckily finding things to print is as simple as a Google search. There are many sites where people share their creations for free and all you need to do is download, send to your printer through special software called a Slicer and bam! you are a 3d printing nerd. The open-source community is thriving in the 3D printing world and finding answers to questions is very easy.

Just look around your house and see if anything needs fixing.

Quick fix

My clothes horse had some broken missing clips which hold the whole thing together and with a quick search of Thingiverse.com I was able to find someone who had the same issue and kindly designed and shared their fix. Thanks, Danrico. Within no time I was able to have it fixed and save it from being dumped. It also saved me over €15 from buying the parts online.

I have also fixed my fridge door which was another crazy-priced part to buy that I was able to sort from the comfort of my desk. You start to understand that this tool can start paying for its keep on day one.

Improve upon

But soon you will need a particular fix that nobody else has encountered. I bought this nice Radio alarm clock and although it is very good. It has one big design flaw. I love my snooze function and when I am waking in the morning I usually hit it three times. Unfortunately, the designers of the clock made the snooze and stop buttons right next to each other and in the early blurry-eyed morning, I would hit the wrong one and sleep happily away like a baby, making the whole house late. This needed a fix.

This was the first design I made and printed. A button extension. I know it is not that amazing but it has changed the game of snooze. A simple tactile button on a button.

Learning how to do designs for yourself can be a bit difficult to get your head around but there are several commercial 3D design tools available to make the process easier. I am a skin flint and have decided to learn the open-source alternative Freecad. It isn't easy to use but there are some good courses on Youtube to get you started. One of the biggest problems with commercial software is that they are all moving to a subscription model so, you will never own it and as the price creeps up and you have learned the program you will forever be in their debt. Freecad is free and although difficult to start with will hopefully improve as Blender has when more people joined its community.

My button took me around ten minutes to learn how to make.

Adaptation

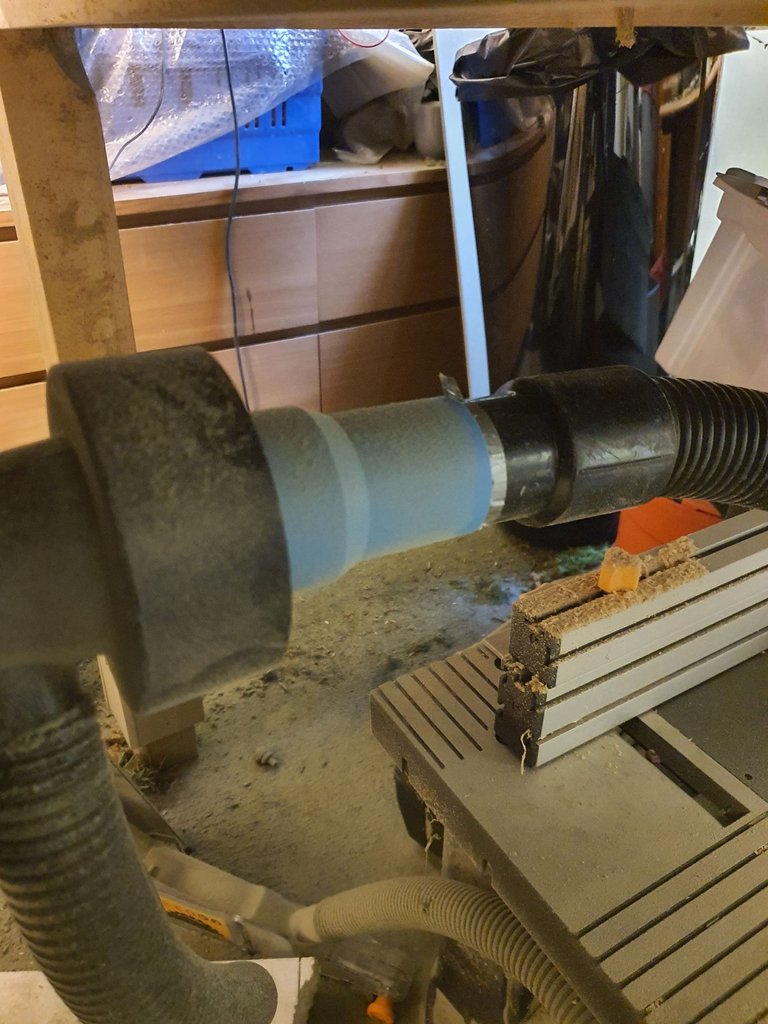

Another annoyance I had was that in my workshop I have all these different tools that produce dust but the dust extraction ports are all different sizes and none of them fit my dust extractor shop vacuum.

A few more minutes in Freecad and I was able to design one for each. Making it much easier than gaffa-taping the vacuum hose each time I want to use it.

I know, again, it is a little thing. But this I believe is how you get started. Fix the world around you and learn by doing. With each project, you will get better, faster and inspired to make other things.

My latest project is this phone holder for my telescope. It allows me to use the good camera on my phone to capture video and stills with ease. It is still a work in progress with this being version 3. I could not find one online or as a 3d print to fit my telescope and phone so I had to make my own. When finished I will do my part for the community by also making the design free for anyone who needs it.

Here is a test shot of an electrical connection box on the moon. I am sure I will be able to get it better and be able to read to smallest writing.

Like a virgin

As a maker and tinkerer, the 3D printer is a great addition to your tool chest and although I am only getting started it has helped expand my way of thinking about the material world.