when we arrive at our indian house there are plenty of coconuts awaiting us. from the oldest dry ones we make cocnut oil. this process requires many steps, none are particularly difficult but it is quite time consuming.

lots of whole dry coconuts need to be peeled

i use a simple but effective low-tech tool. with it i can peel about 150 cocnuts in an hour. i press the coconut onto the sharp pointed top and lift the lever to split the husk. turn the coconut and repeat a couple of times

and the outer husk can be pulled away

that gives us a pile of husks which can be used as firewood or sold for the coir. unfortunately during the covid nonsense the local coir factory closed down and never reopened

now the hard shell must be removed.

for that i use a typical indian chopper and get the whole inner coconut

loose in 1 or 2 quick blows.

so now we have lots of shells. these are good for grilling they burn very hot due to the oil in the shell but they are slow to ignite and last just long enough to cook a meal.

now we have baskets full of coconuts that need to be chopped and graded.

the best quality ones we keep as halves and use almost daily when making curries and more

the others get chopped into smaller pieces for drying

this one is ideal for food grade coconut oil

some have become brown and will be used to either to make massage oil or the brownest ones used for lamp oil. those that have sprouted and turned black are put in the compost.

when this bucket is filled it's ready to be sun dried

we lay out some plastic on the roof terrace and put the best ones to dry. these we cover with a coarse netting to keep the crows away.

the massage/lamp oil ones are placed open on the terrace. they are not so valuable so if the crows or a monkey or two take some we don't worry much

they dry for at least 3 days in direct sun

food grade copra and

lamp oil grade copra ready to go to the oil mill 2 kms away in town

the owner and the workers are in full swing but luckily there are not so many people delivering their copra today. we have to wait until our turn, about 20 minutes

the lady before us is finishing.

the pressed oil being funneled into her containers.

like most marketing this is a social event with time to chat and look around. once the motor is started the oil mill runs continuously.

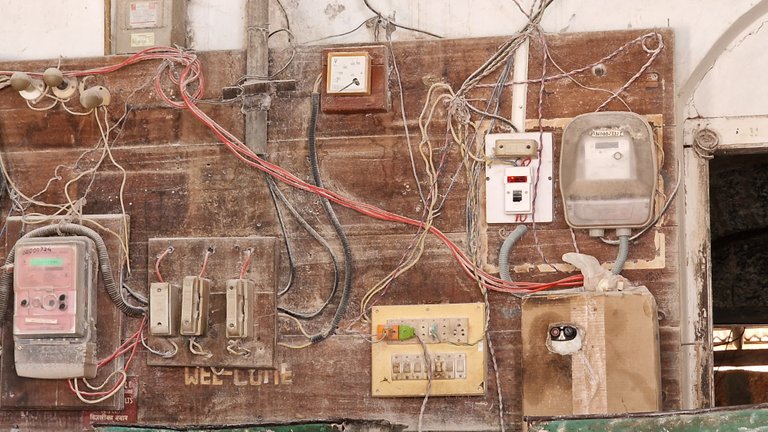

the electricity board has it's 'charm'

there is a flour mill beside the oil mill and they both run on the same motor but with separate belts on each side

now they are ready to take our copra. it's hot working the mill so one of the workers is usually shirtless

but all are barefoot

the best copra goes in first

and soon our oil starts pouring down as the miling machine spins. it is filtered first with a coarse strainer. then through a fine one.

small particles clog the flow and need to be removed. that is a sign that we are almost finished.

clumps of pressed remains after the oil is separated can sold to the mill or kept. they can be used to feed cows or chickens or composted and used for fertilizing the coconut trees.

out of 10 kilos copra we get a little more than 6 kilos oil. 3 bottles: food grade. massage and lamp oil. we put them in the sun to settle and clarify. there is still moisture in the oil which evapoarates in the sun . if not the oil will spoil in a few months.

when settled we pour into glass containers for storage and add a little cane jaggery to soak up any remaining moisture this keeps the oil nice and sweet. the bottom dregs needs to settle more in a tall thin bottle.

in one season we can expect about 60 kilos of oil so we need to start over and peel some more coconuts.