Materials used in roof covers.

https://images.ecency.com/p/2gsjgna1uruvGBHDnRaj2z6FsL6XEQR3pnqa26GnVrVBmiqZ6Ay4YqsXyd9FowEVQLdb8db8xcqhpzqrRnXg9EYCYYDV3yfxJF28ygejxAJiaXUj5Y.webp?format=webp&mode=fit

Hello friends, welcome to my blog; In this publication I will touch again on the topic of roofing, this time roofing, here there are three most important materials to take into account when making this roof, such as the waterproofing, the gutters and the tile.

The construction system that we are going to address is the most popular where I live, it is simple and just right for such a pleasant climate in terms of temperature and humidity, because in terms of rainfall and wind its strong events have occurred.

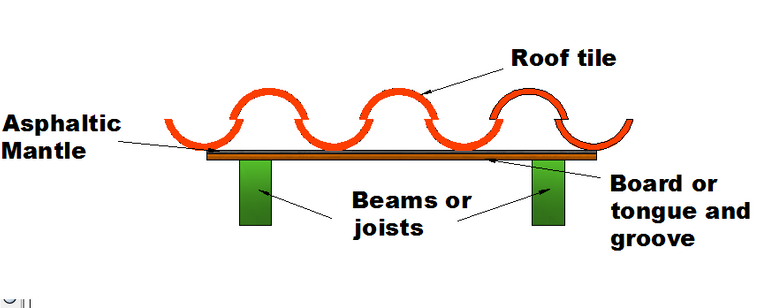

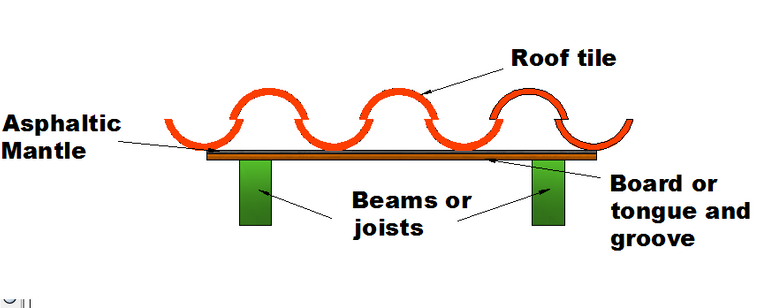

If sometimes it rains very hard, but the temperature is constant throughout the year, therefore, it is very rare to see an isolated roof in this city, in short, this simple roof is a wooden structure supported by wooden or metal beams, tongue-and-groove slats are nailed on top of this to then apply or install a waterproofing material, and lastly, clay or clay tiles are placed.

The most outstanding metallic elements are: the channels that are in charge of directing the water to the drains and the flanges that prevent leaks, this is the construction system roughly, the details and variations depend on the construction itself.

Roof to be restored, it has some leaks in several points, it also has mold, fungi and some plants.

This cover was almost completely rebuilt after being used for 45 years. Throughout this time, occasional interventions were made due to small leaks, but over time the water seepage worsens and the wood wears down due to humidity or by insects begins to collapse.

These are the three most important materials to take into account, the first thing that tends to fail in a roof is the waterproofing, the asphalt layer, therefore choose the most durable one you can afford, there are different thicknesses of 3.5 mm or 2.7 mm, the thicker the more expensive, but worth the investment for fewer headaches.

Asphalt layer with aluminum foil

There is an asphalt layer with aluminum foil and fiberglass reinforcement in the middle. This layer was designed to waterproof flat concrete roofs, where the sun's rays hit it directly and are reflected by the aluminum fill, helping to reduce the temperature inside the building, the manufacturer indicates that its durability is five years.

Channel without recent maintenance.

The channels and flanges are the second elements that commonly fail and consequently leaks appear, require greater thicknesses of metal sheet, in my opinion 24 gauge is fair and no less important is the paint with which these metal elements are protected, if you can pay apply an epoxy anticorrosive and do not forget to require another coat of paint as a finish.

We pass to the wood the most commercial board or tongue and groove is of these dimensions; 80 millimeters wide x 7 millimeters thick, quite thin but it is just right as long as the joists are at a distance of 40 centimeters, these sizes of slats are usual for hardwood species, but in pine it is possible to find a slightly thicker about 9 millimeters approximately.

In terms of durability, the cover that today serves as an example was built in Samán and served for 45 years, but of course this time will vary depending on how aggressive the xylophagous insects are in the area where the cover is located and the control methods are ignored. of pests to combat them.

The wood that I recommend thinking about the environment and depending on where you are, it is better that you choose native woods, otherwise the pine whose origin is from plantations and is immunized by the vacuum pressure method is the most suitable.

exotic wood

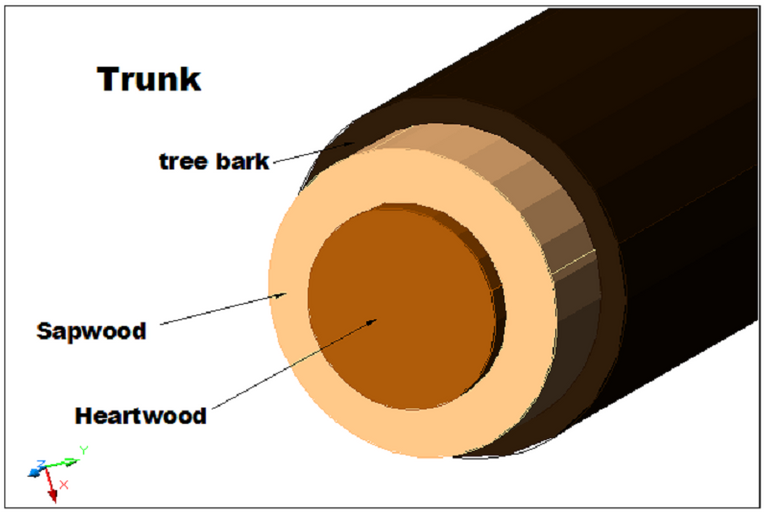

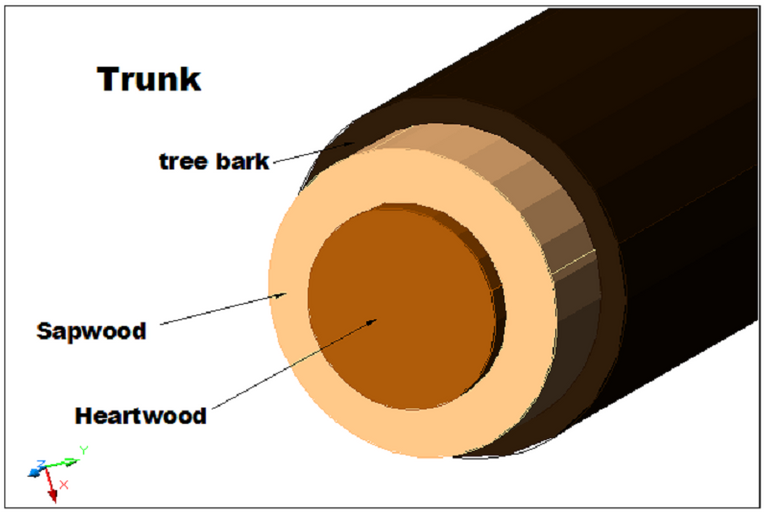

Another option is exotic hardwoods, very beautiful and durable, although the other side of the coin is irrational deforestation, archaic machining and consequently the appearance of multiple defects; Sellers commonly call macana wood that is free of sapwood, thus referring to the board that does not present sudden changes in tonality, yellowish white lines, in technical words, they call macana to the cuts that are exclusively heartwood.

Very simplified diagram of a trunk

The sapwood are strips of different shades and softer than the rest, with the drawback of being the areas most prone to attack by wood-boring insects, so that it is completely clear: this is the heartwood, the central part of the trunk, the most resistant and this is the sapwood.

Example between hardwood and sapwood

Later I will publish how I repaired a roof that had serious but correctable leaks, with several options, some cheaper than others.

I hope the information is useful when making a decision, do not forget to support me and we will read next time, bye.

All images including schematics, photos and models are mine