Soap production involves dissolving different chemicals in water and continuing stirring to form a homogenous solution. This post is all about liquid wash (soap) production and how to produce a homemade liquid soap machine like this

This machine has the following features;

- Twenty-five (25l) liter capacity

- Three different mixing speed

- Auto volume detention in Litre

- User display system

- 300W power rating

- manual controlled discharge system

- Stress-free loading system through a funnel

Arduino is a microcontroller board with Atmega 3328P microcontroller chip. This board was used to program this mixer and the circuit was designed using the Vero board . The agitator was constructed using 1/2" PVC pipe with a combination of elbow and Tee junction.

# WORKING PRINCIPLE #

Ultrasonic sensor HSR05 was used to monitor the distance between the top of the container to the next obstacle which can be the base of the plastic or the level of the water. This distance is subtracted from the total height of the mixer. This depth is the difference between the two heights, this depth when multiplied by the base area of the content will give the exact volume in the container. With the aid of a 1602 liquid crystal display, all the required data is been displayed on the screen. I used a variac to vary the applied voltage to the motor thereby, generating different speeds for the mixing operation.

MACHINE PRODUCTION

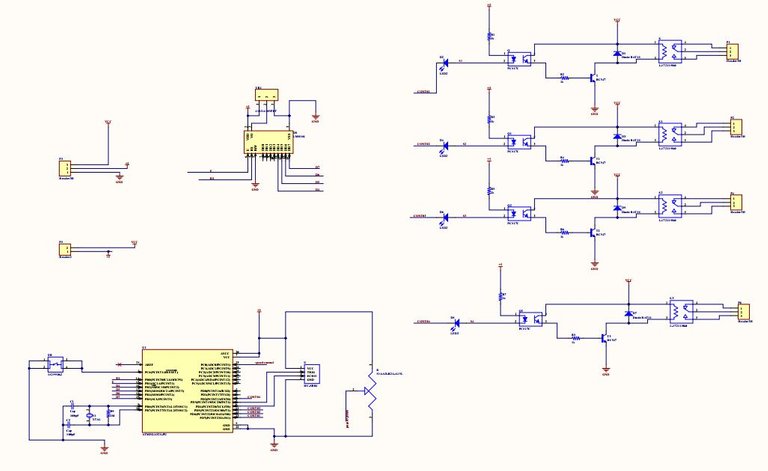

- Develop the needed schematic diagram (here I'm using Altuim designer)

2 ) Solder it into PCB using Vero board

This connection must be neatly soldered on the PCB like this ;

3 ) Programming the Arduino:

Here is the code that was for the Mixer, you can copy and paster to your Arduino IDE

#include <LiquidCrystal.h>

LiquidCrystal lcd(rs, en, d4, d5, d6, d7);

const int pingPin = 9; // Trigger Pin of Ultrasonic Sensor

const int echoPin = 10; // Echo Pin of Ultrasonic Sensor

long duration, inches, cm;

float height=27.0;

float volume=0.0;

void setup() {

Serial.begin(9600);

lcd.begin(16, 2);

lcd.setCursor(3, 0);

lcd.print(" POPOOLA ");

delay(3000);

lcd.setCursor(4, 1);

lcd.print("MIXING MACHINE ");

delay(3000);

lcd.clear();

}

void loop() {

volume=height-cm;

lcd.setCursor(0, 0);

lcd.print("MIXING ");

delay(1000);

lcd.setCursor(6, 0);

lcd.print(". ");

delay(700);

lcd.setCursor(8, 0);

lcd.print(". . ");

delay(1400);

lcd.setCursor(10, 0);

lcd.print(". . . ");

delay(1000);

lcd.setCursor(1, 1);

lcd.print("VOLUME= ");

lcd.print(volume );

lcd.setCursor(13, 1);

lcd.print("Lts");

delay(3000);

lcd.clear();

pinMode(pingPin, OUTPUT);

digitalWrite(pingPin, LOW);

delayMicroseconds(2);

digitalWrite(pingPin, HIGH);

delayMicroseconds(10);

digitalWrite(pingPin, LOW);

pinMode(echoPin, INPUT);

duration = pulseIn(echoPin, HIGH);

inches = microsecondsToInches(duration);

cm = microsecondsToCentimeters(duration);

Serial.print(inches);

Serial.print("in, ");

Serial.print(cm);

Serial.print("cm");

Serial.println();

delay(100);

}

long microsecondsToInches(long microseconds) {

return microseconds / 74 / 2;

}

long microsecondsToCentimeters(long microseconds) {

return microseconds / 29 / 2;

}

3 . The Agitator

This helps in mixing the liquid mixture into a homogeneous solution.

4 Complete the machine

LIQUID SOAP PRODUCTION

Soap and liquid disinfectants are major household consumption everywhere in the world. There are various types of soap based on their physical looks; Powered are called detergents generally, liquid is called wash and solid is called soap. These are the list of chemicals you will need if you want to produce liquid soap;

1)Nitrosol: This serves as a thickener in the production of liquid soap.

2)Sodium Lauryl Sulfate: Its lowers surface tension between ingredients

3)Caustic soda: This is dirt and stain removal

4 ) Soda Ash: It regulates the concentration of caustic soda

5 ) Texapon: It serves as a foaming agent

6 ) Sulphonic Acid: Foaming and cleaning agent

7)Perfumes: sweet fragrances

8 ) Sodium tripolyphosphate: Strong cleaning agent

9 ) Colour: Appearance

10 ) Water: Dissolving all the chemicals

Add all these above-stated chemicals in the above order but remembered to premix everyone one of them with water and later dilute the solution with excess water. For 25l liquid soap production, 1/8kg of each of the chemicals is good. You should have this king of production at the end