Well Hello There Horsepower Lovers!!

On The Wait For Parts!

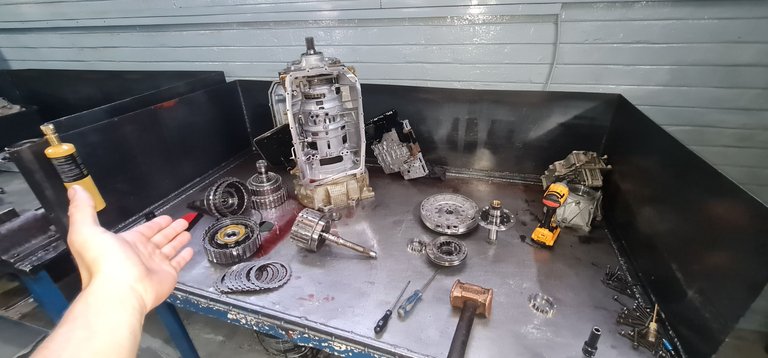

So yesterday I pulled a transmission with yet another torque converter problem or well something related to a slip in the converter area! After a tear down we were able to see clearly where the problem lay and it wasn't exactly where we thought it would be!

We were assured that the problem was converter related because of the electrical faults it gave! But that is why we tear everything down ey!

I forgot how easy it was!

Let's Start With A Coffee!

You can't start a day without a nice hot coffee right? This at-least is a very awesome cup! It's also bean to cup so it's going down nicely!

I did powerwash the underside of the vehicle before removing the transmission and that helped a lot for the stripping process of it all! We did replace the oil with some fresh oil though, after doing a valve body swap on the vehicle!

I ensured that the stripping table was well and perfectly clean to catch all of the newly used oil. That shit is expensive and it can still be used for a long time to come! Although I would prefer to have new oil added again after a tear down!

Glad I started a week earlier with work this year, it feels like everything is back to normal once again!

I am already flowing in the rhythm! First off the valve body!

After that it's the pump that needs removal, the plan here was to swap out the torque converter and then reassemble a new pump that can run on a differently designed torque converter.

So far the job was an easy one!

Only Then We Noticed!

Only then did we notice that the torque converter was in-fact fine! It was the d-shaft that has slight scores marks on them!

That means there will need to be a shaft replacement and also a pump replacement! Well the fortunate thing is we are already halfway there on plans! Not sure where we will find a shaft this quick, we might need to wait for the parts to arrive in a couple of weeks!

Might Be The Reason For A Slight Problem!

Well the score marks are not really visible but they are there and that means why the car only really gave slight problems when hot and none at all when cold, amazing stuff right! How can steel work so interesting!

The guys designing these things are really whack smart!

You might want to zoom in a little on the picture but it's clear! Unfortunately we will have to wait for parts now!

I can't exactly get a nice photo of the inside of this setup, it's showing the first bush that mates with the d-shaft but the second after that I can't get it to focus nicely on it!

So getting the bushes would be a easy thing but the actual shaft we would have to wait for!

Connecting the people of #HIVE across South Africa. #hive